|

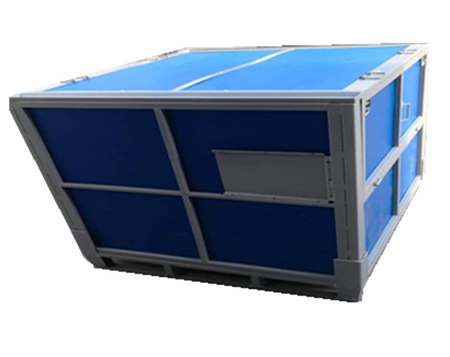

Metal material boxes are divided into corrugated plate metal boxes, hanging metal boxes, steel metal boxes, steel metal boxes, grid A type metal boxes, folding grid type metal boxes, steel legs welded steel panels. High quality corrugated plates are used to weld the four sides of the upper side of the box type metal bin, and high quality cold drawn steel wire and high quality profile are used to weld the upper part of the net type metal bin, which is the same as the storage cage. Surface treatment with shot blasting technology can better remove rust and oil, eliminate the pollution of sewage caused by acid pickling and phosphating in the past, more in line with environmental protection requirements, and is conducive to the export of steel metal boxes. In the later stage, 180 degree spraying and baking technology is adopted to make the product appearance neat, beautiful and durable. The dimensions of metal bin can be made according to the actual requirements of customers'products. When purchasing metal bin, you should consider the external dimensions of your product, the larger load-bearing requirements of your design, whether your metal bin is used for warehousing or for turnover, and whether it needs to be stacked, etc. According to the actual needs of users, we produce design drawings and customize them.

|